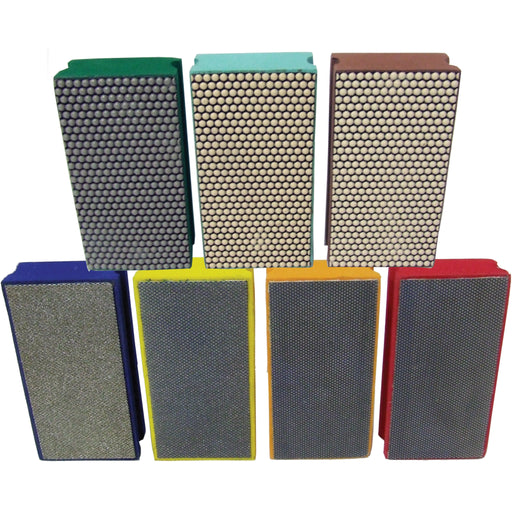

Polishing Equipment for Tile & Stone Finishing

Polishing equipment includes tools and accessories used to refine surfaces, smooth edges, and produce consistent finishes on tile and stone. These products support multiple stages of the finishing process, from surface preparation and correction to final polishing and buffing. Using the right polishing equipment helps improve surface appearance, reduce imperfections, and support professional-quality results.

This collection includes machine-driven and hand-operated polishing tools along with compatible accessories used on ceramic, porcelain, and natural stone surfaces in residential and commercial applications. Polishing equipment is commonly used in tile installation, stone fabrication, and surface restoration projects where controlled finishing and repeatable results are required.

Polishing systems often combine polishers, polishing pads, backer pads, buff pads, and specialty accessories to create a complete surface finishing setup.

Types of Polishing Equipment

- Polishers: Electric or pneumatic tools used to drive polishing and buffing accessories

- Polishing Pads & Discs: Used for surface refinement through multiple grit stages

- Buff Pads: Designed for final finish and surface enhancement

- Backer Pads: Provide support and attachment for polishing pads and discs

- Brush Wheels & Felt Wheels: Used for specialty finishing and surface treatment

How to Choose the Right Polishing Equipment

- Material Type: Ceramic, porcelain, or natural stone

- Stage of Polishing: Surface correction, refinement, or final finishing

- Tool Compatibility: Confirm arbor size, thread type, and mounting style

- Wet or Dry Use: Choose equipment designed for the intended operating method

Where Polishing Equipment is Used

Polishing equipment is used for tile edges, cutouts, corners, countertops, backsplashes, floors, walls, and stone fabrication projects where consistent surface finish is required.

Finishing Quality & Surface Control

Using the correct polishing system and accessories helps improve finish consistency and reduce surface imperfections. Polishing equipment supports controlled material refinement across multiple stages of the finishing process.